How Lean Improvements at SureKap Are Speeding Up Builds and Aiding Machine Quality

At SureKap, innovation isn’t just about new equipment. It’s also about improving how we build every machine. Over the past year, several members of our operations and assembly teams—including contributions led by Mohamad Ammar, (who has been developing new jigs, refining tooling, and improving process documentation)—have pushed forward Lean-inspired upgrades that are already paying off in speed, consistency, and quality.

Standardized Jigs: More Precision, Less Adjustment

SureKap has added custom jigs that set exact alignment points for key subassemblies. Instead of relying on individual technique, the jig locks in the correct dimensions every time. “Repeatability is the real win,” Mohamad notes. “It removes guesswork for the builder and reduces fine-tuning later.”

5S Improvements That Keep Technicians Moving

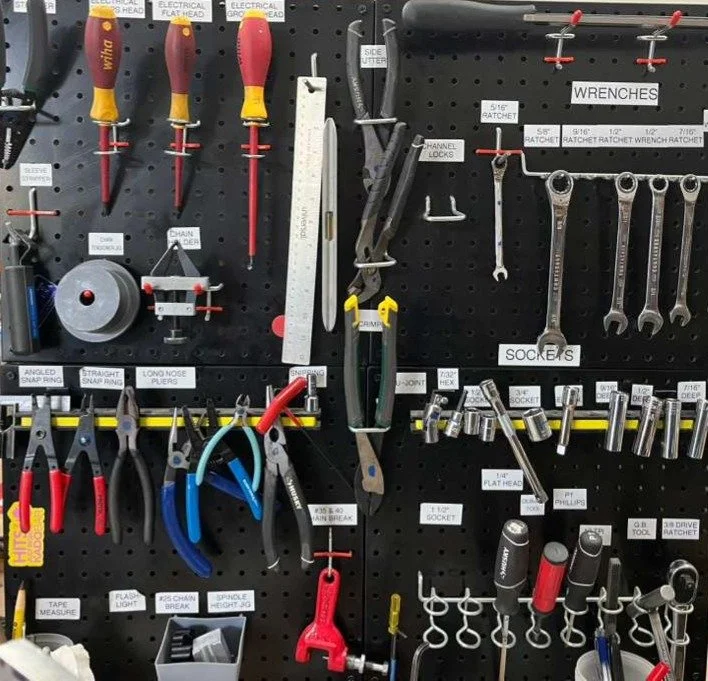

After completing Lean/5S training through Georgia Tech, Mohamad contributed to broader shop-floor changes that streamline daily work. Tool Walls now replace scattered toolboxes, putting common tools in predictable, easy-to-reach locations.

Hardware at designated workstations ensures that all required hardware for specific assemblies is available directly at the assembly station, eliminating extra trips, reducing errors, and cutting wasted motion — one of the “8 wastes of Lean.”

Capturing Expertise Before It’s Needed

Experienced builders often rely on instinct—great for quality, tough for consistency. To preserve that expertise, the team has been documenting key sequences and assembly steps. “You can follow a drawing,” Mohamad explains, “but if you do things in the wrong order, the machine will fight you. That’s what we’re clarifying.”

Better Processes = Better Machines

Every improvement—jigs, tool organization, kitting, documentation—reduces friction inside the shop so we can deliver stronger, more reliable equipment and shorter lead times. “As we simplify internally, customers feel it externally,” Mohamad says. “That’s the whole point.”

Customer Impact:

Shorter build cycles

Fewer mistakes caused by incorrect hardware

More predictable delivery timelines